Laser Hardening for Industrial Applications

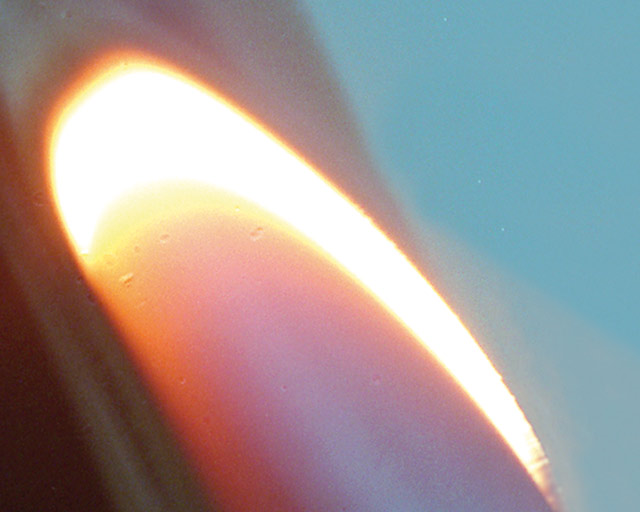

Laser hardening is an innovative process for surface hardening of metals in which a laser beam heats the workpiece surface in a targeted manner. The rapid and controlled heating and subsequent self-cooling creates a martensitic microstructure that makes the surface of the material significantly harder and more wear-resistant. This process enables precise control of the hardness and depth of the hardened layer without subjecting the entire workpiece to thermal stress.

Typical applications can be found in mechanical engineering, the automotive industry and in tools where high wear resistance and durability are required. Laser hardening is often used for the treatment of gears, shafts and cutting tools. The process is efficient, environmentally friendly and enables the machining of complex geometries. Local heat treatment means that even components with sensitive areas can be reliably hardened.

The development of a new type of hardening process for precipitation hardening materials can be regarded as a special scientific achievement. A major objectives was to increase the service life of turbine blades made of precipitation hardening steel 16-4 PH. Such hardened turbine blades are now used in more than 50 turbines in large power plants.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS