Additive Manufacturing of the Large Optical Bench for the Advanced Telescope for High Energy Astrophysics

Motivation

The large-scale scientific mission NewATHENA, rescoped by the European Space Agency (ESA) in November 2023, will explore the hot and energetic universe using advanced X-ray technology. The key component of the telescope will be hundreds of Silicon Porous Optics (SPO) modules arranged in an optical bench with a diameter of around 2.7 meters. Considering the overall size, the delicate cellular structure and the high aspect ratio in combination with the material-related challenges of Ti6Al4V, Additive Manufacturing using Direct Energy Deposition (DED) is a promising alternative to conventional processing.

Objectives and Approach

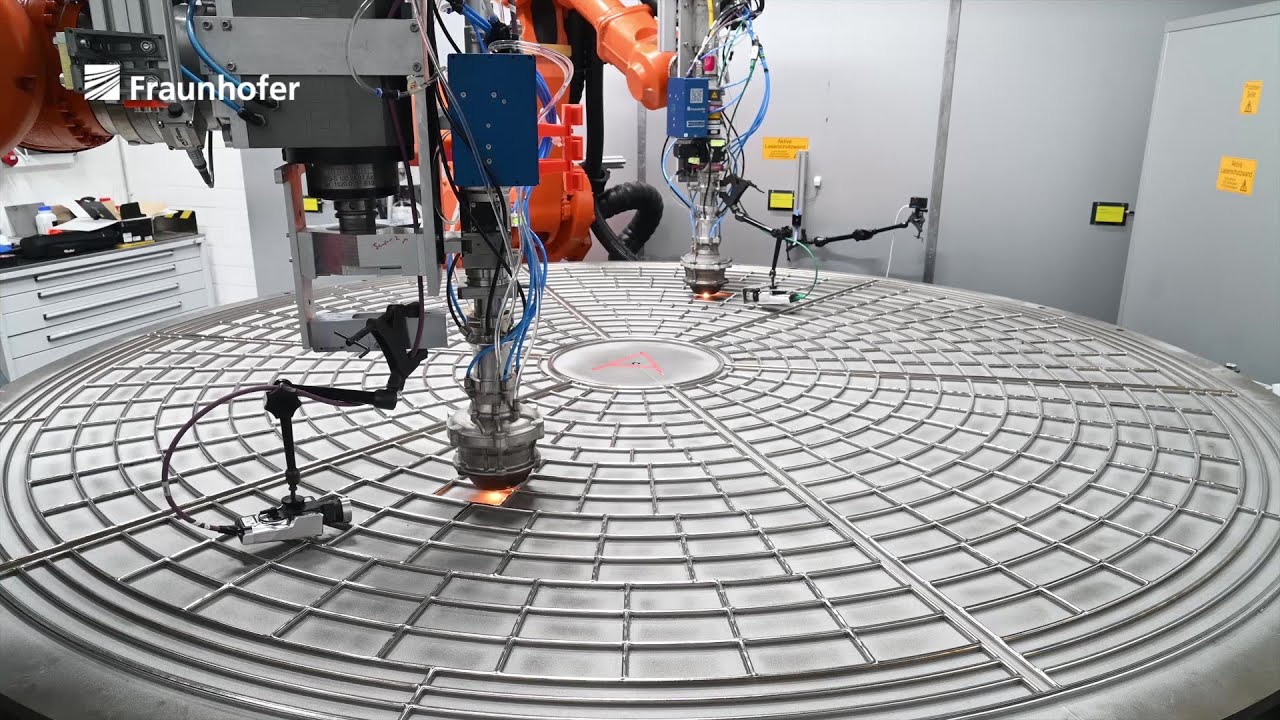

An initial research activity based on direct contracting of the European Space Agency addressed the scaling and parallelization of process equipment and the basic feasibility of a hybrid approach combining Direct Energy Deposition and milling. Several development steps have been covered in a holistic manner starting with the system engineering of the production site. Subsequently a representative optical bench (diameter 1.5 meters) has been manufactured. Lessons learned were incorporated into a following maturation activity and led to extensive adjustments to the design, process, build strategy and part handling to address fundamental challenges such as deformation and residual stresses.

Innovation and Future Prospects

Furthermore a novel approach for a local shielding of the DED process has been integrated facing the embrittlement of Titanium alloys due to the formation of “alpha case” driven by oxygen pick up. The suitability of the developed technologies and workflows for the NewAthena Mission are now being evaluated through the manufacture of a second representative, full-scale breadboard of 2.7 meters. The novel end-to-end manufacturing approach, the geometrical complexity as well as sheer size of the Titanium component could be considered as unique.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS