System technology

View into the opened PVD coating chamber with coated test sheets

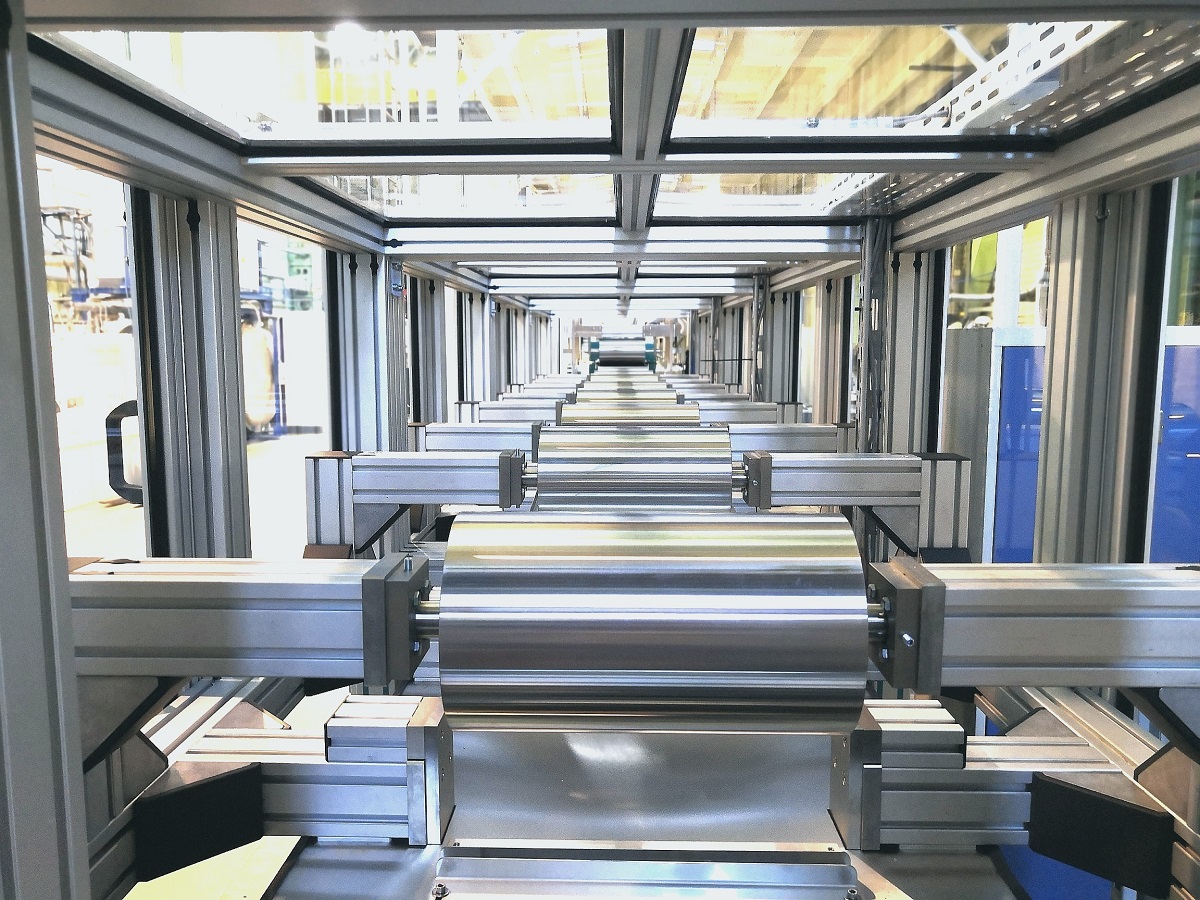

Roll-to-roll system for continuous, time- and cost-saving coil coating processes of fuel cell stacks.

The spectrum of system technology available at the Fraunhofer DOC® project group includes:

- modular spArc® evaporator technology with industrial PVD large chamber system with a usable diameter and height of 1.2 m each (batch load up to 2 tons),

- in-house developed high performance PVD technology for the metal band coating under rough vacuum conditions,

- latest wire arc spray technology with spraying cabin, vacuum chamber and the possibility to support the process with laser power,

- 3D capable laser and laser-MSG hybrid welding system (gantry portal system, robot systems) with mobile 8 kW fiber and 4 kW Nd: YAG-lasers.

Additional systems from Fraunhofer IST and TKSE are available for joint projects. TKSE, IST and IWS jointly operate the DOC®’s modular and 80 m long sheet metal band coating pilot machine. The team offers research and development on vacuum coating processes for the continuous surface refinement of thin metal sheets.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS