Hydrogen technologies occupy a key position when it comes to the energy transition and achieving agreed climate targets. As an alternative to fossil fuels, green hydrogen (H2) can significantly reduce carbon dioxide (CO2) emissions and accelerate the necessary transformation of economic sectors toward climate-friendly value creation. In its function as an energy carrier, hydrogen will contribute decisively to the energy industry and to modern mobility solutions in particular. Due to its broad range of applications, hydrogen can serve as an alternative approach to battery technology for cars, trucks, aircraft, rail vehicles and ships, for example.

Highly Scalable Production Technologies

In order to meet the future expected high demand for powerful electrolyzers and fuel cells, it is essential to develop highly scalable production technologies for automated mass production and to transfer them into large-scale application. With their comprehensive expertise in surface, material and laser technologies, Fraunhofer IWS scientists contribute to unlocking the existing potentials for industry in preparation for the upcoming hydrogen era.

Research Focuses

Fraunhofer IWS develops sustainable material and manufacturing concepts for electrolyzers and fuel cells, indispensable for an economically and ecologically efficient use of hydrogen. A further key area includes solutions for safe and flexible storage as well as transport of hydrogen – thus ensuring cutting-edge energy cycles.

Electrolysis

- Water electrolysis: Additive manufacturing of graded porous transport layers (PTL) made of titanium

Additive Manufacturing

- Additive manufacturing of bipolar plate prototypes for flow field analysis to determine flow velocities

Additive Manufacturing

- Thermal coating: Development of catalyst surfaces for proton exchange membranes (PEM), methanol synthesis and artificial photocatalysis

Thermal Spraying

- Analysis of electrochemical properties and interface problems by means of electrochemical methods

Electrochemistry

- Gas purification: Measurement of porosity characteristics and purification of process gases

Gas and Particle Filtration

H2 Infrastructure: Storage, Transport and Distribution

- Hydrogen pressure tank manufacturing, cryogenic applications and components for e-fuel engines

Joining

Fuel Cells

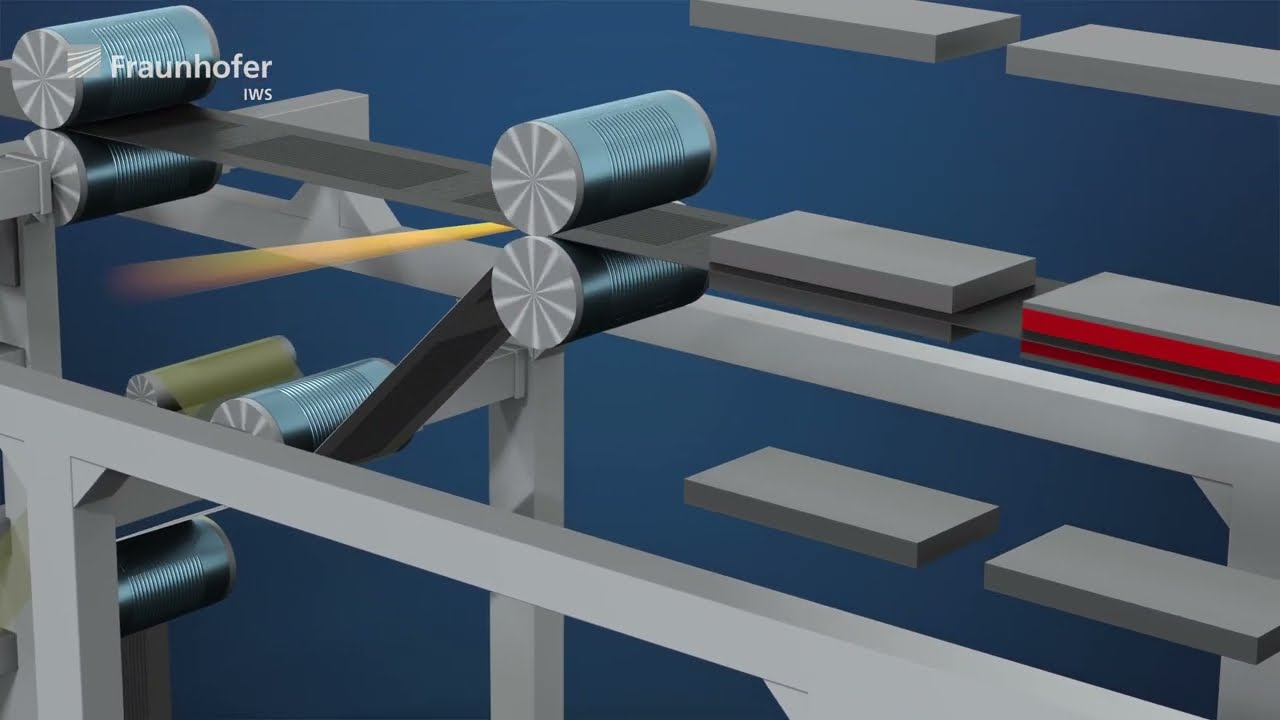

- Production of metallic bipolar plates by roll-to-roll (R2R) process

Dortmunder Oberflächenzentrum DOC®

- Solvent-free coating of gas diffusion membranes with microporous transport layers

Chemical Coating Technology

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS