Fraunhofer IWS enginieers utilize comprehensive high end equipment as well as long year experience to perform applied research projects in the field of micro patterning and precision machining with (ultra)short pulsed laser beams. Targeted applications are the miniaturization of functional elements in machines, systems, vehicles, instruments and medical devices. Examples include the fabrication of 3D structures of micro millimeter dimensions and surface texturing on polymers, metals, ceramics and quartzite and biocompatible materials. Laser based cleaning and coating removal processes are further fields of development. To the same extent as structuring, diagnostics is crucial for understanding processes and samples. Therefore, the working group has specialized in optical laser process characterization with high-speed camera technology.

In an application-oriented manner, we accompany our partners from initial feasibility studies through process development to implementation in series production. We efficiently contribute our expertise and many years of experience to projects with industrial customers and within publicly funded projects.

Our Range of Services Includes:

Based on our profound technical expertise and extensive experience with industrial customers and publically funded projects, Fraunhofer IWS offers the following capabilities:

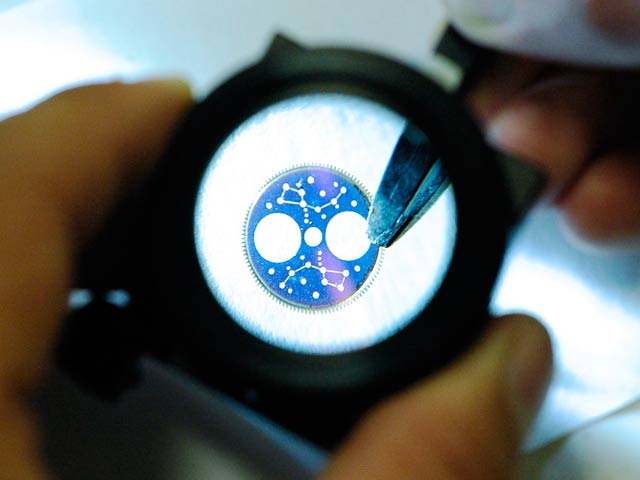

- Laser micromaterial processing by means of short and ultra-short pulsed lasers

- Ablation, structuring, engraving, drilling, cutting of any materials such as metals, plastics, semiconductors, natural materials, ceramics, thin films and heterogeneous materials (e.g. fiber composites or multilayer materials)

- Modification of surface topography to adapt triological, chemical, biological or physical properties as well as interface design for material joints, e.g. for fiber-reinforced plastic composites (joint pretreatment)

- Laser cleaning and decoating for technical and restoration applications

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS