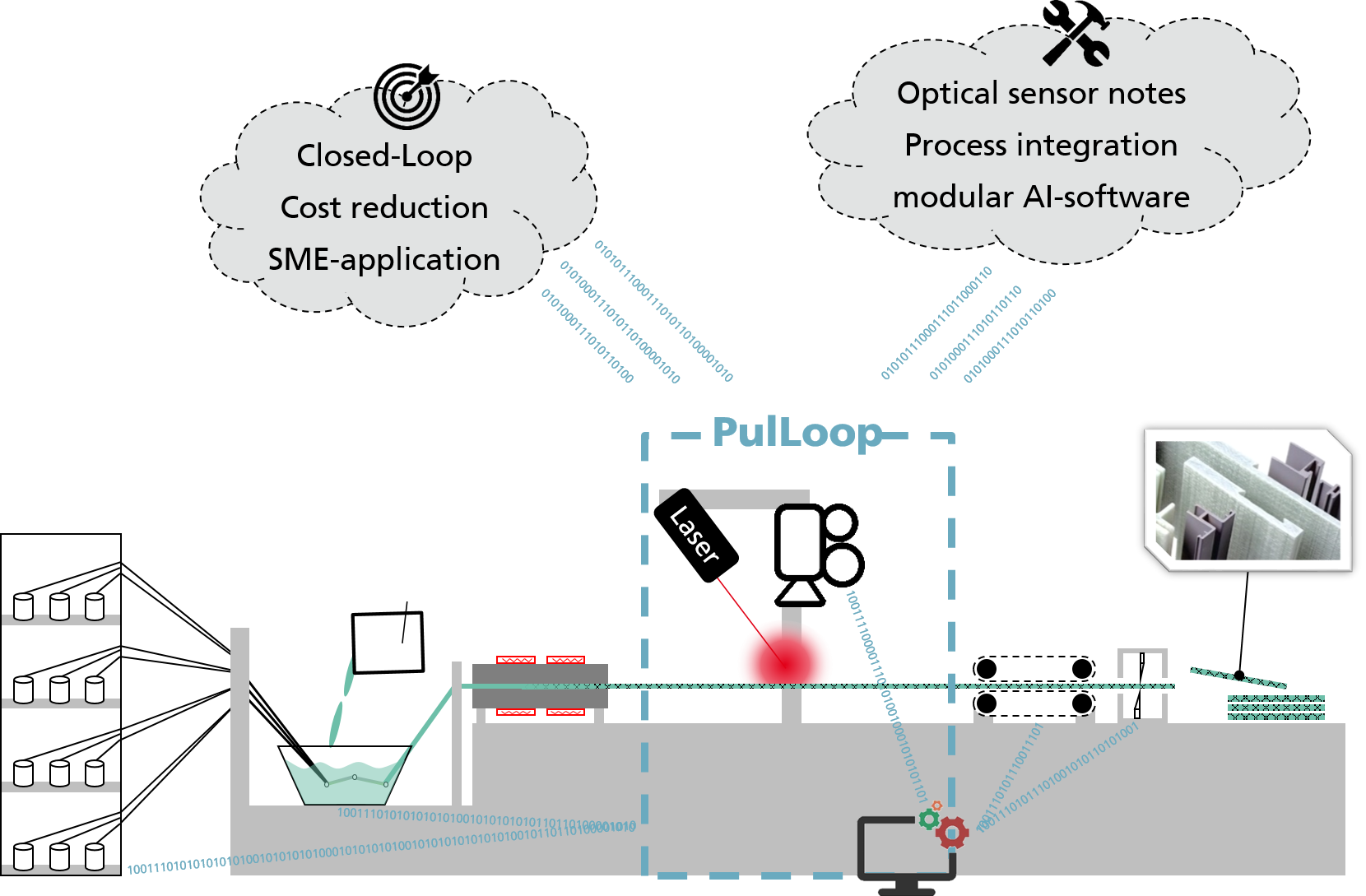

Development of non-contact, process-integrated measurement technology for continuous production processes in the digital manufacturing cycle

Subproject: Development of innovative optical surface measurement technologies based on scattering sensors and AI-supported image analysis

Motivation

The pultrusion technology, a continuous pulling process for manufacturing fiber-reinforced plastic profiles (FRP), offers great potential, particularly for lightweight construction in small and medium-sized enterprises (SMEs). A central challenge is ensuring consistent product quality through reliable inline monitoring to prevent production interruptions and high rejection rates. Currently, SMEs lack cost-effective, integrated measurement systems for real-time quality control of profiles, which can lead to competitive disadvantages in cost-intensive and documentation-heavy industries like automotive and energy sectors.

Project Description

In the PulLoop project, the Fraunhofer Institute for Material and Beam Technology (IWS) and the Fraunhofer Institute for Casting, Composite and Processing Technology (IGCV) are developing cost-efficient optical measurement technology for pultrusion processes. Using optical surface measurement sensors and AI-based image analysis, an innovative solution for precise and continuous quality monitoring is being created. The combination of advanced sensors and intelligent software enables seamless inline characterization, forming the basis for a closed-loop production approach. This approach facilitates data-driven process optimization and significantly reduces rejection rates through objective quality controls.

The commissioning of new profile geometries often involves temporal and financial uncertainties due to the subjective nature of past experience. Moreover, the lack of spatially resolved component monitoring complicates compliance with documentation-intensive industries. The technology developed in the project enables SMEs to economically utilize pultrusion for small batch sizes. It also offers flexibility for use in other industrial applications and supports a quick and low-risk introduction of new profile geometries. The modular software architecture allows the solution to be flexibly extended with sensor networks and additional sensors (sensor fusion) without impacting production quality. This cost-efficient innovation is internationally relevant, particularly for industries under high cost pressure, such as automotive and wind energy.

Goals

Existing solutions often rely on expensive measurement technology, whose high investment costs are economically prohibitive for most SMEs. The PulLoop project, therefore, pursues a scalable approach: The required measurement technology is comparatively cost-effective and is analyzed using an intelligent software solution. This keeps investment costs low for each company while the software development costs are distributed among many users. This approach makes state-of-the-art technologies economically accessible for smaller businesses.

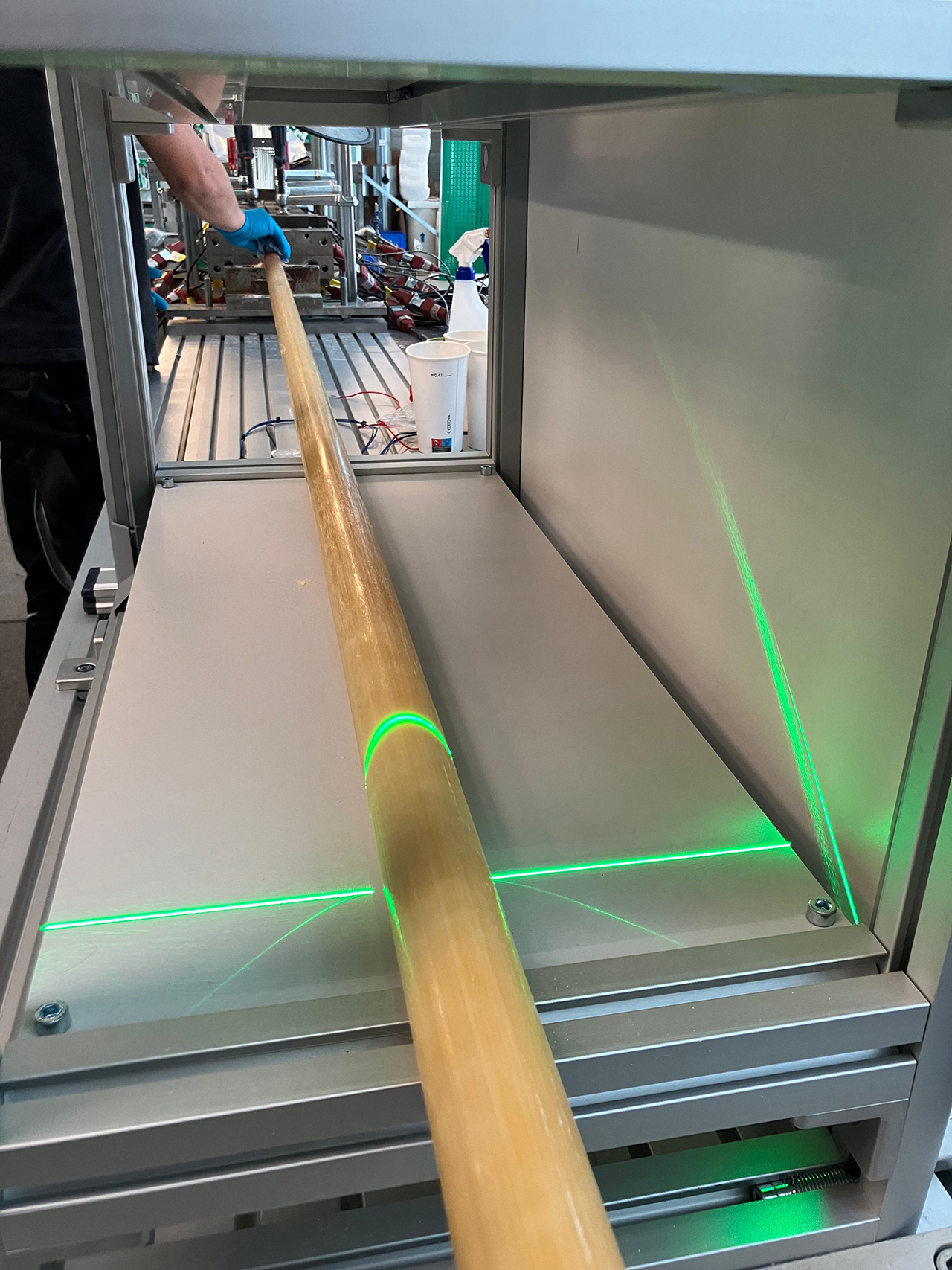

Subproject IWS

Within PulLoop, Fraunhofer IWS develops innovative optical surface measurement technologies based on scattering sensors and AI-supported image analysis. This combination of cost-effective sensors and advanced data evaluation strategies enables inline characterization of profiles and closed-loop control, making it particularly suitable for use in medium-sized enterprises. The goal is to enhance the quality of pultruded profiles and significantly accelerate the setup of pultrusion processes.

Subproject IGCV

Fraunhofer IGCV focuses on improving the efficiency, robustness, and usability of the process. Through intelligent process data management, innovative AI methods, and consistent knowledge modeling, the production process is optimized, and expertise is structured for transfer to SMEs.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS