The Fascination of Materials: Innovation for a Sustainable Future

Sustainable Material Design as Response to Resource Bottlenecks

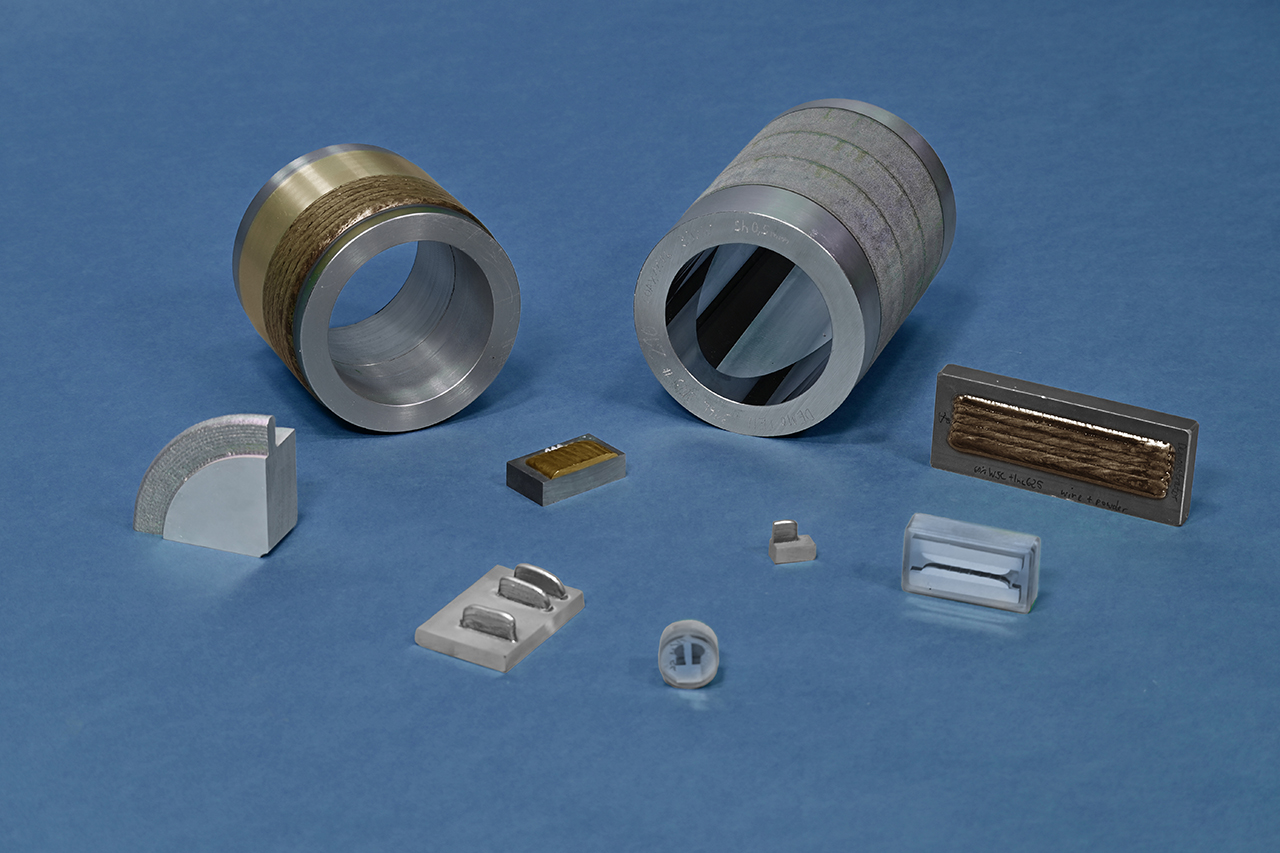

Finding solutions to potential resource bottlenecks requires sustainable material design. New material compositions enable more environmentally friendly ship propulsion systems, more economical aircraft engines or even lighter electric vehicles. At Fraunhofer IWS, the Competence Field Materials Characterization and Testing led by Prof. Martina Zimmermann is developing the “recipes“ for tomorrow‘s materials. The unique feature: Here, new alloys can be generated and analyzed directly using additive manufacturing methods. The 3D printers at the institute allow the newly developed recipes to be tested long before they are used in industry.

“The shortages of strategically important metals such as titanium and cobalt are worsening and have even extended to magnesium,“ explains Martina Zimmermann. “Their availability fluctuates, and we must react to this volatility.“ In addition, raw materials such as cobalt are often mined in Africa under questionable working conditions. “The transformation of German companies towards a sustainable circular economy also requires a new approach to rare high-tech materials,“ adds Dr. Jörg Kaspar, Group Manager for Materials and Failure Analysis. “We need better approaches to recycle products made from these materials and feed them back into the material cycles.“

To this end, the Competence Field Materials Characterization and Testing concentrates on special materials expertise with excellent access to the necessary technical equipment. While other organizations require extensive trial casting before testing new materials, this can be done quickly and efficiently with the sophisticated equipment for additive manufacturing technologies and testing technology at Fraunhofer IWS. For example, the institute combines powder- and wire-based additive manufacturing (AM), uses lasers of different wavelengths and power classes that also allow the processing of metals such as copper, and can precisely control the supply of several starting metals for new high-entropy alloys. The Fraunhofer researchers offer decades of experience in process design, metrology and the control of additive processes as well as the characterization and testing of AM structures. Consequently, they provide partners in the industry with well-founded solutions for material-based innovations.

Paradigm Shift: “As Good as Necessary“ Replaces “As Good as Possible“

Once the “recipe“ has been designed, the team uses particular analysis and testing technologies to examine the material and determine whether and how it might replace conventional alloys. “The principle of ‘as good as necessary‘ replaces the older maxim of ‘as good as possible‘,“ emphasizes Martina Zimmermann. After all, this approach allows the development of options to counter the drastic increases in raw material availability and price development of titanium or cobalt.

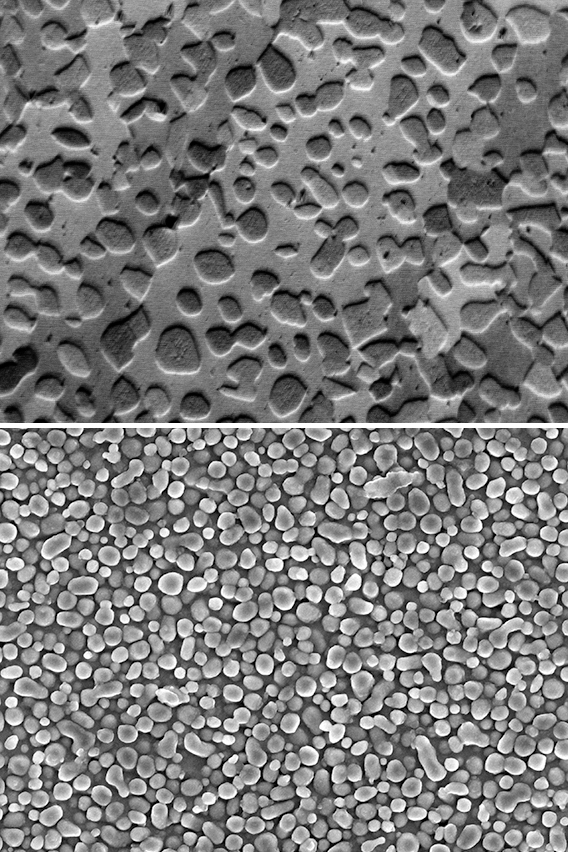

By combining thermodynamic state calculations, laser-based synthesis processes, and high-throughput screening, Fraunhofer IWS efficiently determines the properties of each alloy required for the application. This includes questions such as: What strength does the new material exhibit? How corrosion-resistant and durable is the material? What temperatures can it withstand? Together with partners, the scientists must clarify whether the additively generated layers and structures will retain the measured properties before they are transferred into practice, when they are cast for example.

This still-young method for designing and testing new materials could trigger an evolutionary leap in the industry. In the past, structural materials, their pre- and post-treatment, and possible applications were passed down from generation to generation like traditional cooking recipes, explains Martina Zimmermann. The production, pre- and post-treatment of structural materials still use established “recipes“, some of which are considered unique selling propositions for material manufacturers. “Our approach to modern material design, on the other hand, can be compared to a ‘molecular kitchen‘, where additive manufacturing and modern coating technologies as a material screening method enable an almost infinite variety of chemical compositions.“

Marine Propulsion Systems without Lubricating Oil within Reach

Numerous industries, ranging from automotive engineering to the shipbuilding industry, can benefit from these developments. Fraunhofer IWS has already identified several applications; for instance, the materials of the next generation will enable shafts for ship propulsion systems that work without lubricating oil and all its ecological disadvantages, instead using seawater for lubrication, reports group manager Jörg Kaspar. Coatings and components for aircraft, preventing oxidation even in humid environments and high temperatures, offer another application scenario. These properties may be necessary for water-enhanced turbofans (WET) – engines designed to drastically reduce carbon and nitrogen oxide emissions in aviation.

This is just the beginning. Industry observers see enormous commercial prospects for next-gen materials. Studies from the USA* assume the market for advanced materials will grow by five to ten percent per year until 2030.

* Sources: USD Analytics, Advanced Materials Market, Global Markets Estimates, Global Market Watch

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS