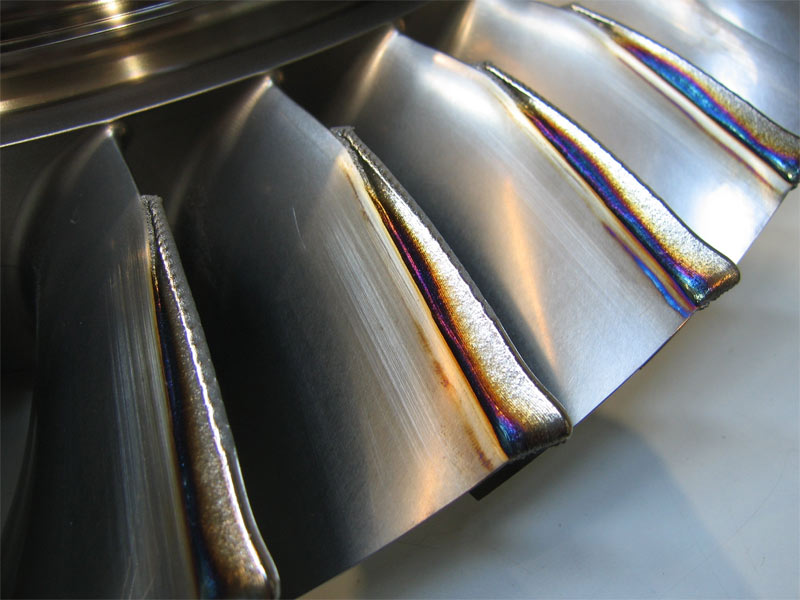

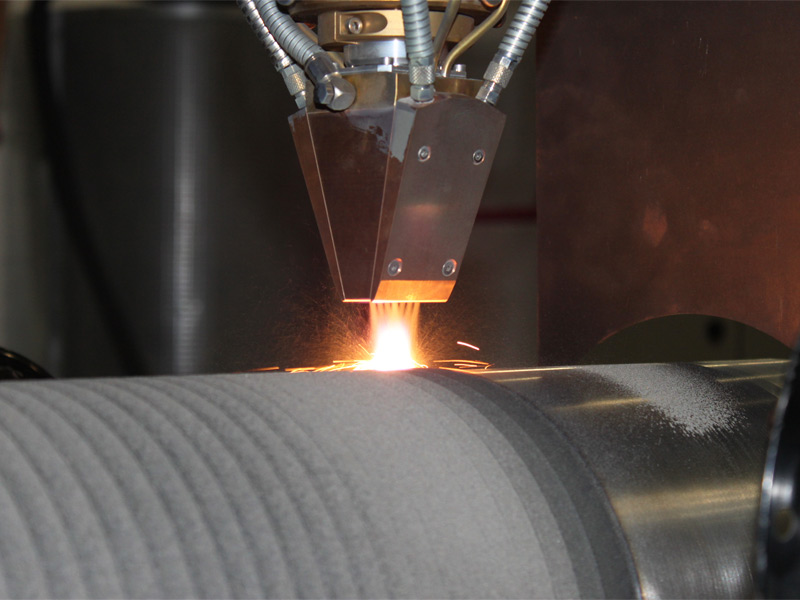

Laser cladding is a high-precision process in which material is applied to a workpiece surface using a laser beam. The base material is melted locally and a filler material in powder or wire form is added at the same time. The laser beam generates a concentrated heat source that ensures rapid and controlled melt pool formation.

Typical applications can be found in toolmaking, for repairing and reinforcing components and in the automotive and aerospace industries. The process enables high precision and minimal thermal stress on the workpiece. It is particularly suitable for processing complex geometries and applying wear-resistant coatings. The flexibility and accuracy of laser cladding make it a preferred method for demanding industrial applications.

The Fraunhofer IWS is your reliable partner for the processing of real components, the development of system engineering solutions and the transfer of laser cladding into industrial practice.

Our Range of Services at a Glance:

- Process development for powder and wire cladding

- Inductively assisted deposition welding (hybrid technology)

- Simulation-supported material and process development

- Production of processing heads and machine integration

- On-site user support during the production launch

We support you from the initial idea through to implementation in your production.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS