The worldwide increase in energy consumption and the ambitions of efficient energy use are leading to a growing demand for high-quality materials for energy transmission and conversion. There is also a demand for technological and plant engineering solutions for improving properties that can be integrated into existing production processes and lines.

One area of application is the optimization of the magnetic properties of grain-oriented electrical sheet, which is preferably used for transformer cores. Targeted laser treatment can reduce the losses that occur during transformer core remagnetization and thus increase the efficiency of energy transmission.

Domain Refinement of Electrical Sheets

The process engineering approach is based on the refinement of the magnetic domains. For this purpose, local stresses (thermal domain refinement) or structural defects in the form of trenches (heat-resistant domain refinement) are created in the material. The laser beam acts as a tool whose energy input can be influenced by the optimum choice of process parameters and optical configuration. The laser beam, which is moved perpendicular to the rolling direction, generates lines at an equidistant distance and thus influences the domain dimensions.

The system technology solution developed with partners allows integration into production lines and enables continuous treatment of the strip at speeds of up to 160 m/min.

System Technical Solution

The lasertronic®SAO x.x/12D laser beam deflection optics was developed for laser domain refinement of continuously moving grain-oriented silicon steel strip. The beams from up to four laser sources are focused on the material surface. The single laser spot is moved at speeds up to 300 m/s perpendicular to the direction of the moving strip. The light energy absorbed by the sheet generates thermal stresses in the structure of the material. As a result, the magnetic domains are refined. The lasertronic®SAO x.x/12D system uses 12 galvanometer scanners in a patented arrangement to generate 800 parallel lines on a 1 m wide strip with four independent laser beams per second.

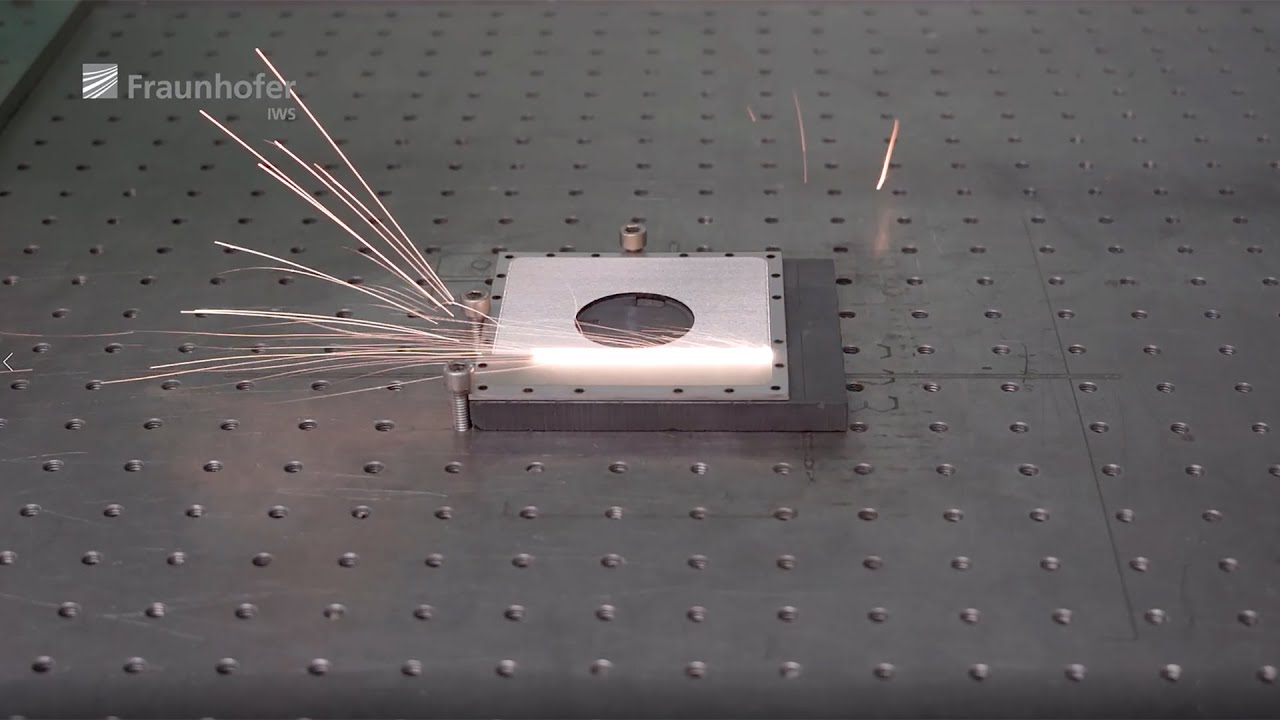

The unique LMDR test system developed at Fraunhofer IWS is used for process and system development. The system has two independent laser beam paths and a setup corresponding to the production systems. The uniaxial material transport is performed via a sample table. The use of different laser sources allows, for example, the influence of the wavelength to be investigated. Adapted processing parameters can be worked out for customer materials, which can be implemented directly with production systems. The changes in magnetic properties determined for single strips or Epstein sets are an optimization criterion.

Find more information about LMDR in this scientific publication.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS