Organic electronics already provide beautiful rich colors in modern televisions, enable elegant designer lamps and are the characteristics of high-end smartphones. Organic electronics require very little power, are extremely thin, and are often even transparent and flexible. In the near future, this technology is likely to generate many more innovative consumer products, medical devices and photovoltaic applications. Material and surface inspection, for which hyperspectral imaging (HSI) is a perfect tool, may play an important role in their manufacturing process. Fraunhofer IWS has further advanced the technology in order to design the “imanto®” platform. imanto® is capable of quickly detecting even the smallest defects and the slightest deviations from the ideal structure of barrier films and identifying their water vapor transmission rate. After all, this rate is a key factor in determining the service life of flexible organic electronics products, such as organic light-emitting diodes (OLEDs) or solar cells (OPVs). The previously unthinkable measurement possibility can give an enormous boost to the development, production and application of barrier foils and thus to the entire organic electronics industry.

Organic electronics has pushed requirements for barrier foils to an extremely high level

“Barrier foils have indeed been in use for a long time, for example in the food and pharmaceutical industries,” explains Dr. Wulf Grählert, who heads the Optical Inspection Technologies working group at the Fraunhofer Application Center for Optical Metrology and Surface Technologies AZOM, a Fraunhofer IWS branch. “In these areas, the protection of sausage, coffee, cheese and other products against moisture, bacteria or loss of flavor really has always been a priority.” But organic electronics have made the requirements for the permeability of such barrier foils with respect to water vapor extremely stringent. Food packaging foils, for example, must not allow more than ten grams of water vapor per square meter to pass through within one day. For tablet foils, this water vapor transmission rate (WVTR) is only one tenth to one hundredth of a gram per day and square meter of foil. OLEDs, however, require barrier films that allow only a few micrograms of water vapor per day to pass through. In addition, up to now, measurements of the water vapor transmission rate have required a very long time. The measurement results of OLED barrier foils are often only available after several weeks. Fraunhofer IWS scientists have now managed to reduce the inspection time for barrier foils in organic electronics to just two to three hours.

EU project “OledSolar” opened the door

The EU project “OledSolar” opened the door to a new solution approach. In the course of this project, 16 institutes and technology companies from all over Europe are developing advanced manufacturing and inspection methods for the industrialization of organic electronics until spring 2022. In this project Fraunhofer IWS has started to design a barrier inspection system using a fundamentally new approach: Measurement is no longer performed on water vapor permeating the barrier, but solely on the foil, which significantly determines this permeability. In two and a half years of work, scientists and technicians have produced more than 100 barrier film samples in a roll-to-roll process at the project partner Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP, whose water vapor transmission rate was first measured with high precision by the Fraunhofer IWS inhouse developed HiBarSens® technology. Fraunhofer IWS researchers subsequently measured HSI data sets from the samples at various positions and used them to train a model which, based on an HSI measurement, can predict the water vapor transmission rate of the measured barrier foil with sufficient accuracy hundreds of times faster.

AI experiences as well

Processing raw optical data into useful information resembles human vision. Eyes provide the brain with raw color data such as red, green and blue. Thanks to a lifelong training in experience, the human brain is able to interpret this data and perceive and recognize the world. However, hyperspectral “seeing” differs in a decisive way: In order to obtain the crucial information, special data analysis algorithms are required due to the enormous size and complexity of the data recorded in so-called “hypercubes.” Wulf Grählert emphasizes: “No human could evaluate this data conventionally. That's why we apply artificial intelligence methods.” AI also “gains experience.” It learns correlations between cause and effect. For example, the effects of potential foil defects such as scratches, layer defects and inclusions on a hypercube as well as on the foil's water permeability are trained to a model. A sufficiently trained model will subsequently be able to predict the water vapor transmission rate of a barrier foil from its hypercube with high reliability. Measurement and prediction are available so quickly that faulty batches can be detected immediately. In addition, it is now even possible for the very first time to evaluate at which specific points the barrier foils allow more or even less water vapor to pass through.

With faster cameras, the measurement time can be reduced even further, and the more training data AI receives in the future, the more accurate its predictions will be.

The ultimate goal is real-time quality control during foil production, as well as in incoming inspection in the subsequent processing operations. “We see great potential,” emphasizes Wulf Grählert. “This new type of sensor technology significantly shortens inspection time for barrier foils, opens up the possibility of inline quality control, reduces reject rates, and can make OLED and OPV production more cost-efficient.”

Hyperspectral inspector already proved its worth on pizza

Wulf Grählert also sees a wide range of possible applications beyond organic electronics, for example in the electronics and semiconductor industries, in pharmaceuticals or in the food sector. “We have already tested the system with frozen pizzas,” explains the group leader. The system can be used to automatically check whether there is enough ham, mushrooms and cheese on the pizza or whether foreign objects have landed in between. Many other application scenarios in which invisible sample properties are made “visible” are also implementable.

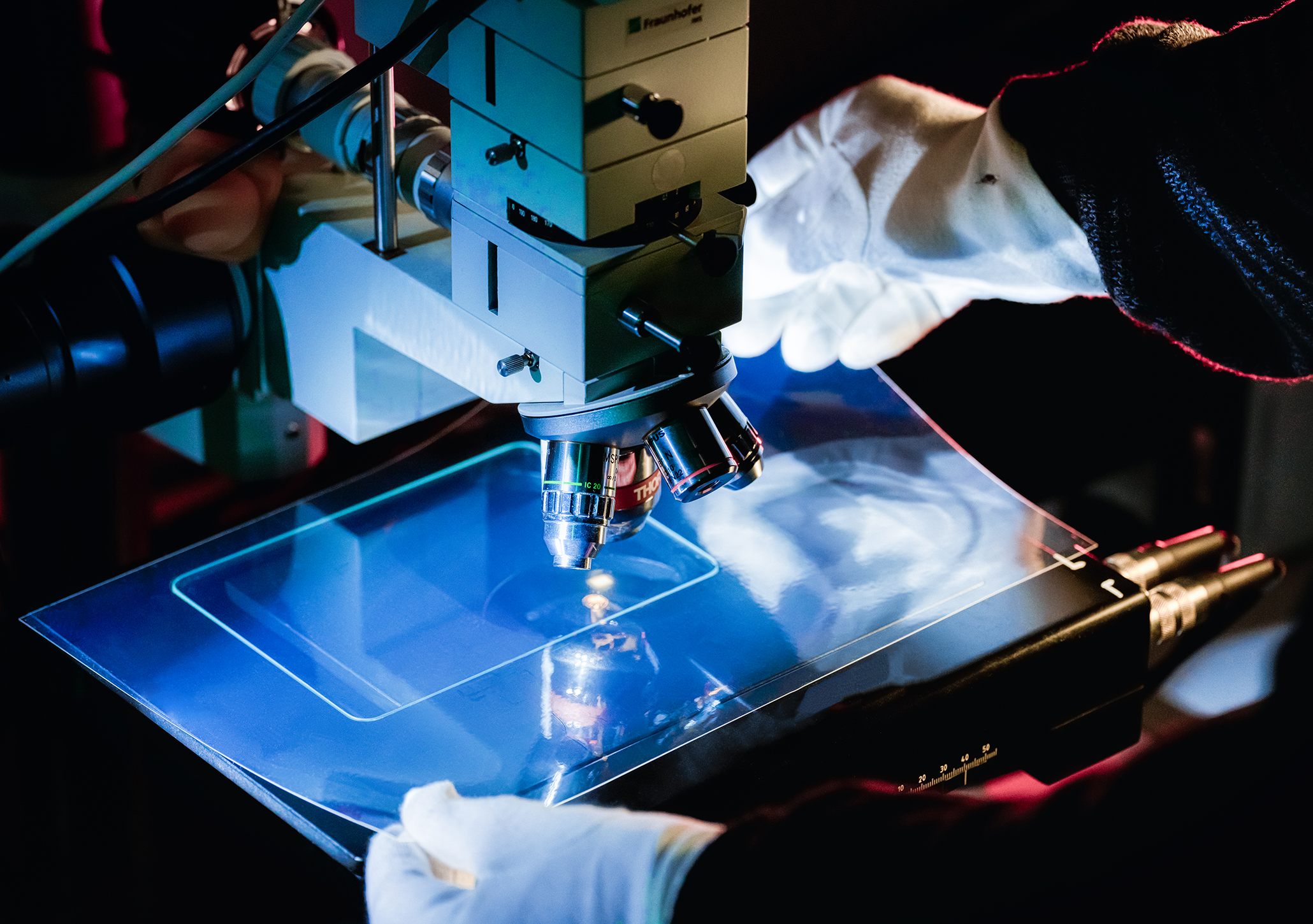

Info box: imanto® The term imanto® refers to “imaging analysis tools”. In the Fraunhofer IWS developed system, an optical analysis head focuses on the foil strip and a spectrometer decomposes the light reflected from the foil in an HSI camera. However, the process does not only happen at one sample point, but simultaneously at several hundred points. The spectrometer visualizes how strongly the foil reflects ultra-violet, green, blue, yellow or infrared rays, for example, at different points. Thus, immediate conclusions can be drawn regarding the properties and quality of the foil. Defects or other “peculiarities” of the foil can only be detected under very specific colored light. Supermarket cash register bill validators, which visualize security features of euro banknotes, are a good example in this respect. In a similar way, the imanto® system generates entire stacks of color-filtered images of the foil under examination and stores them in a so-called “hypercube”. These hypercubes are subjected to specific data analysis in order to calculate the desired target parameters of the foil inspection, for example the water vapor transmission rate of the barrier foil. . |

About Fraunhofer AZOM

The scientists at Fraunhofer AZOM are researching and developing the latest approaches in optical metrology, image processing, process control and surface characterization. They focus on transferring research results quickly and directly into application-specific solutions for industrial processes. To this end, AZOM offers research services such as development and testing of industry-compatible optical measurement methods for various fields of technology. It provides the interface between applied science and industry in the fields of medical technology, automotive engineering, mechanical engineering and semiconductor technology. In optical metrology and process integration, the research spectrum is based on three pillars: service measurements, industrial integration of established technologies and the development of novel measurement methods. Thus, AZOM scientists develop concepts for complex industrial optical measurement methods and system components, characterize surfaces, engineer user-specific sensors and actuators, and offer non-destructive monitoring of processes and components. In the field of laser-based surface technologies, industrial integration and process development constitute the pillars of the service portfolio. In particular, AZOM develops electronic control systems, complex application-specific software solutions and optical system components such as light sources for metrology as well as fiber-based sub-assemblies in combination with free beam elements. In addition, AZOM solves individual problems not yet solvable with the standard technology currently available on the market.

Fraunhofer Institute for Material and Beam Technology IWS

Fraunhofer Institute for Material and Beam Technology IWS